Push and Pull system in logistics: what they are and differences

In an increasingly demanding industrial context, where margins are tightening and customers are demanding flexibility, efficiency in production logistics has become a key factor for competitiveness.

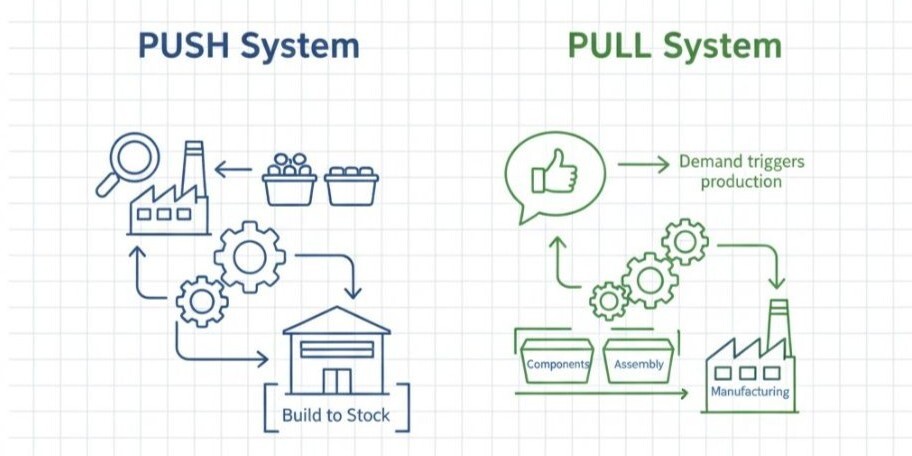

Two of the most commonly used approaches to organise manufacturing and inventory management are Push and Pull systems, two models with opposing philosophies but that can coexist within an intelligent hybrid strategy.

In this article, we explore what Push and Pull systems are, their differences, advantages, and how to integrate them with technologies such as ERP RPS Next, and MES/MOM INEXION to optimise the supply chain.

What are Push and Pull systems in production logistics?

Push and Pull systems determine how production and material flow are planned within the company. The key is when production starts: before (Push) or after (Pull) receipt of the customer order.

Push system: early production based on demand forecasting

The Push system is based on planning and demand forecasting. The company produces based on estimates and keeps inventory on hand to meet future market needs.

This makes it possible to take advantage of economies of scale, reduce unit costs and guarantee immediate product availability. It is the ideal model for sectors with high turnover, predictable demand or seasonal peaks, such as food, textiles or mass consumption.

However, its success depends on the accuracy of forecasts. Over-optimism can lead to overstocking, while a conservative estimate can lead to inventory breakage.

Pull system: on-demand manufacturing and just-in-time logistics

The Pull system works oppositely: production is only activated when there is a confirmed order. In other words, the product is manufactured on demand, adjusting resources and materials to the actual flow of sales.

This approach is associated with the Just-in-Time (JIT) philosophy and the principles of Lean Logistics, which seek to eliminate waste and minimise storage costs. It is common in sectors such as automotive, industrial machinery or custom-made furniture, where customisation and flexibility are priorities.

The great advantage is the reduction of stock, but it requires synchronised logistics, agile suppliers and digital systems capable of responding in real time to the variability of demand.

Key differences between Push and Pull systems

Although both models seek efficiency, their operational fundamentals differ in several key aspects.

| Aspect | Push Production | Pull Production |

| Production start point | Production starts based on demand forecasts and sales plans. | The process starts only when an actual order is received from the customer. |

| Inventory management and procurement | Requires maintaining high stock levels to respond quickly to the market. | Minimises inventories and uses order flow as a trigger for procurement. |

| Flexibility, cost and lead times | Offers fast delivery, but assumes storage costs and risk of obsolescence. | More efficient and sustainable, but may involve longer lead times if responsiveness is not well optimised. |

Advantages and disadvantages of each model

| Push System | Pull System |

| Main advantages | |

|

- It takes advantage of mass production to reduce unit costs. - Facilitates immediate product availability. - Simplifies logistics management in environments with stable and predictable demand. - Allows planning resources, shifts and purchases in advance. |

- Avoids overproduction and improves inventory control. - Allows greater customisation and adaptation to real demand. - Reduces capital tied up in stock and storage costs. - Promotes sustainable logistics practices and energy savings. |

| Common disadvantages | |

| Can generate excess inventory and obsolescence costs. | Requires tighter response times and a very flexible supply chain. |

| Recommended technology integration | |

| Ideal for companies working with ERP RPS Next, where MRP planning and demand forecasting are integrated with purchasing and production. | Integrating an MES/MOM system such as INEXION allows this model to be executed with precision, connecting plant, orders and logistics in real time. |

The ideal solution is usually found in a hybrid Push-Pull model, where the base production is planned (Push) and the final customisation is done on demand (Pull).

How to choose the best strategy for your company

There is no universal model: the choice depends on the type of product, the stability of demand and the technological capacity of the organisation.

Key factors: product type, rotation and responsiveness.

- Standardised and mass consumption products → Push model.

- Customized or complex products → Pull model.

- Companies with mixed production → Hybrid Push-Pull model, adapted to different product lines.

Technology as an ally: ERP, MES and integrated RTLS systems.

Digitisation of the supply chain is essential to implement any of these models successfully.

Systems such as ERP RPS Next enable production planning, inventory control and purchasing optimisation. MES INEXION connects plant equipment with ERP, providing real-time visibility into production progress and material availability.

Combined with an RTLS (Real-Time Locating System), these systems ensure full traceability, error reduction and perfect synchronisation between procurement and manufacturing.

Digitising the supply chain with intelligent tools

Automation and data analysis are now indispensable to remain competitive. Overtel's integrated solutions make it possible to:

- Synchronise inventories between the factory and warehouse.

- Anticipate demand through AI and advanced analytics.

- Coordinate logistics and transportation with connected tools.

With this technological base, companies can apply a dynamic Push or Pull strategy, adjusting their production according to actual market behaviour.

Push and Pull are not mutually exclusive models, but complementary. The key is to combine them intelligently with the help of technology, adapting production to real market needs without compromising operational efficiency.

With solutions such as ERP RPS Next and MES INEXION, your company can connect planning, production and logistics in a continuous and optimised flow.

Contact Overtel and discover how to synchronise your logistics systems to maximise productivity and industrial competitiveness.

.png?width=501&height=92&name=Overtel%20Logo%20Postivo%20(7).png)