Repetitive manufacturing vs. flexible production

In the context of Industry 4.0, repetitive manufacturing vs. flexible production has become one of the most relevant comparisons to define the production strategy of modern factories.

Posts about:

In the context of Industry 4.0, repetitive manufacturing vs. flexible production has become one of the most relevant comparisons to define the production strategy of modern factories.

In modern industry, batch production remains an essential pillar for sectors that require flexibility, quality control and operational efficiency. However, today's challenges - such as changeover times, batch-to-batch cleanups and the need for full traceability - demand a more digital, automated and connected approach.

In the era of industrial digitalization, maintenance has become a strategic factor in ensuring operational efficiency and production continuity.

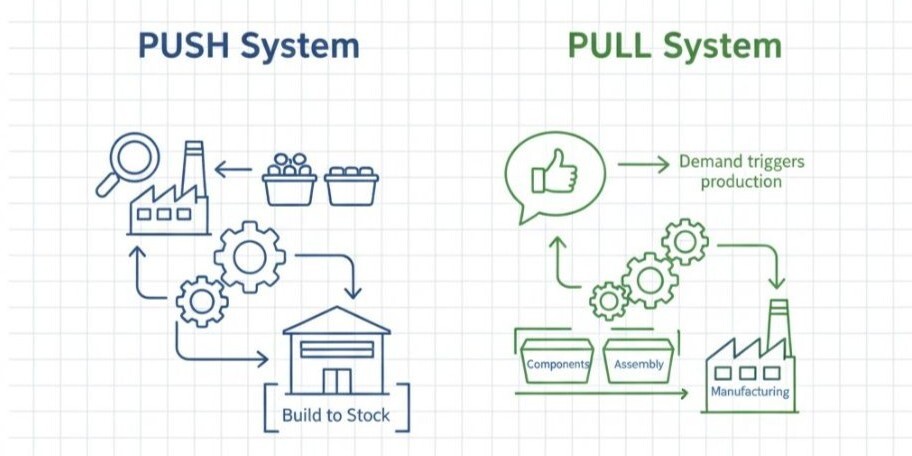

In an increasingly demanding industrial context, where margins are tightening and customers are demanding flexibility, efficiency in production logistics has become a key factor for competitiveness.

COOs drive investment in automation, real-time data and Industry 4.0. But here is the inconvenient truth that consulting firms avoid mentioning: more than half of digitisation projects fail, not because of the technology, but because of a lack of human adoption.

Digital transformation is advancing at an unstoppable pace, and companies that want to remain competitive need to optimize their internal processes. In this context, workflow automation (also known as workflows) has become an essential tool to increase efficiency and improve the quality of results.

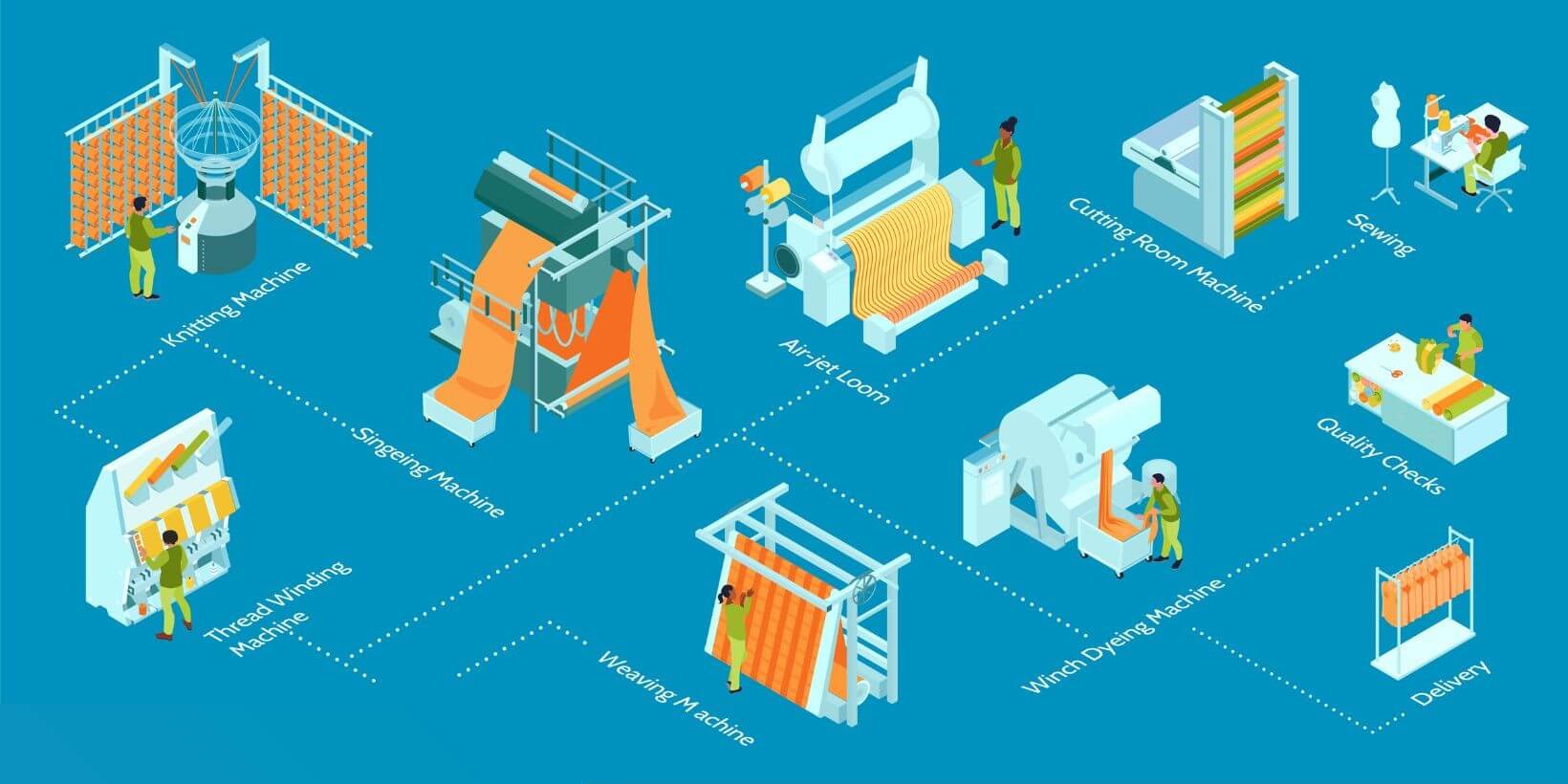

The sustainable textile industry has become a global imperative. Regulatory pressure, consumer demands and sustainability objectives mean that factories must evolve towards more efficient digital models.

Industrial digitisation is advancing rapidly, but so are the threats. Every year, cyber-attacks on companies increase, especially in sectors such as manufacturing, energy, food and logistics, where the convergence between IT and OT systems expands the attack surface.

Smart packaging is revolutionising the way companies manage traceability in the supply chain, reduce waste and improve the customer experience. Unlike traditional packaging, smart packaging integrates sensors, QR codes, RFID or even blockchain, becoming strategic assets within Industry 4.0.

.png)

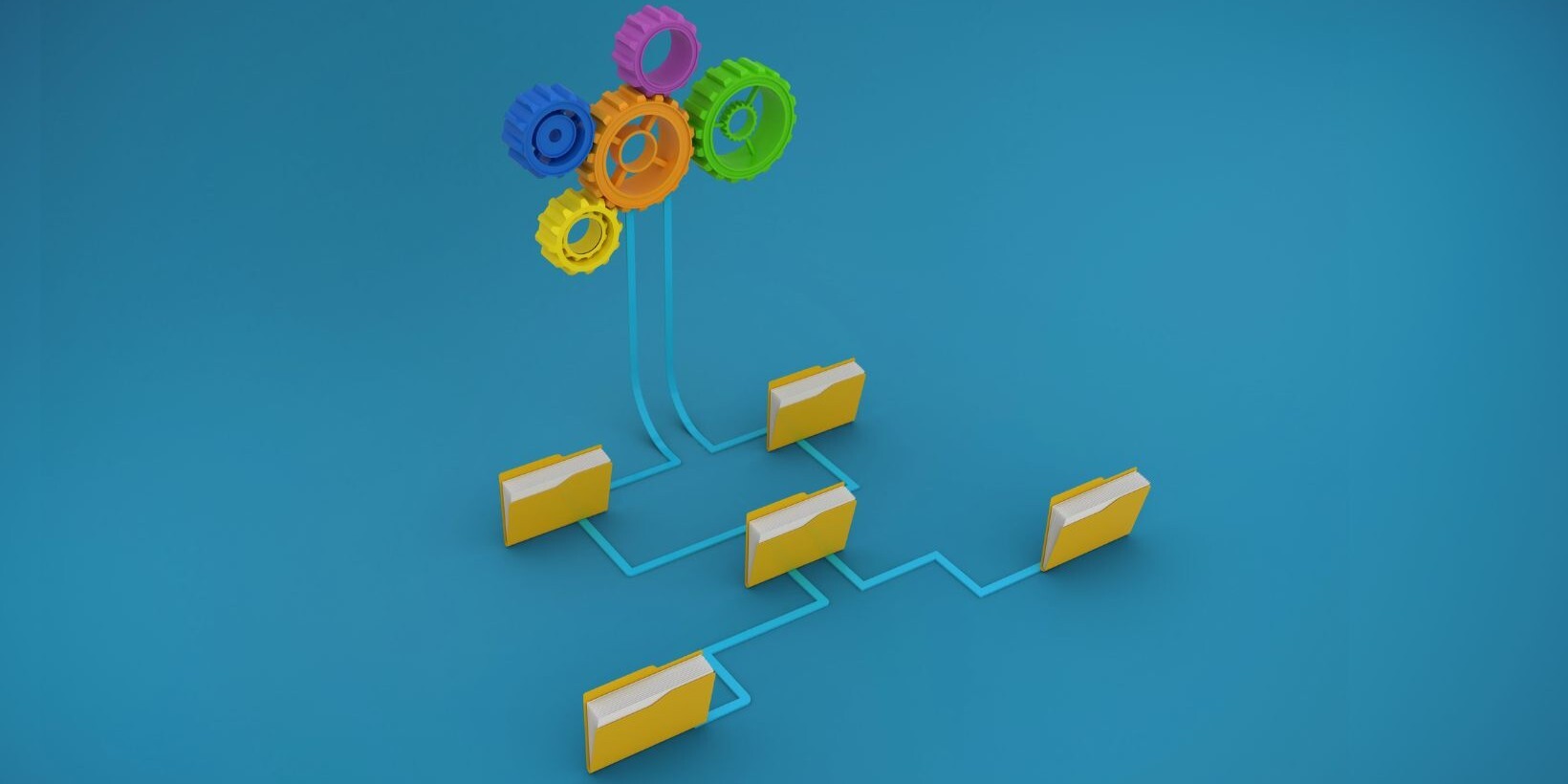

The integration of CAD, ERP and document management is one of the pillars of the digital factory. In many industrial companies, design, administrative management and technical documentation work in silos or watertight compartments, leading to data duplication, errors, delays and cost overruns.

We answer questions and discuss everything you need, with no obligation.